Case Study

Global Bank in Abu Dhabi Adopts IoT to Maximize its Asset Performance and Reliability as a step towards Sustainability

UAE’s largest bank and one of the world’s largest and safest institutions, offers an extensive range of tailor-made solutions, and products and services, to provide a customized experience. Through its strategic offerings, it looks to meet the banking needs of customers across the world via its market-leading Corporate and Investment Banking and Personal Banking franchises.

The Leading bank is rising to the challenge of sustainability, The Facilities Management team aims at optimization of asset performance and energy.

Business Scenario

As part of the sustainability drive, the bank’s facilities management decided to contribute to the vision by optimizing the energy and asset performance by implementing IoT technologies.

Some of the key challenges faced by the client consisted of:

- Increased Operations Cost

- Millions of data point to analyze and difficulty in making decisions

- Diversified traditional platforms

- Increased number of facilities

- Increased Inventory Cost

- No Visibility on Energy Consumption and wastage

- Manual Reporting

Challenges

- Low Visibility on Asset Performance

- Energy Cost Optimization

- High Inventory Cost

- High Operations and Maintenance Cost

- Millions of points to Analyse

- No Central Monitoring

Tools & Technologies

- FacilityConneX

Solution

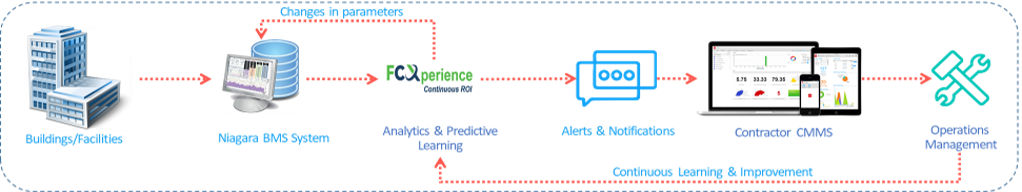

After careful assessment of the clients vision and existing BMS landscape by Intertec, we proposed to implement the predictive analytics platform in one of their old and prestigious facilities with a vintage BMS system. This will help the client and its internal and external stakeholders to understand the return on investment by improving the overall operational efficiency and energy savings both in terms of Electricity and Chilled water. Intertec succeeded in the digitalization of the data and provided both tangible and intangible benefits to the client.

The solution is aimed to enhance the experience of the operations and maintenance team by using the latest technologies like IoT, deep machine learning to understand the current status of the assets/equipment in the building HVAC system and predict the failures. This helps the team to streamline the operations and optimize the resources and time.

Intertec deployed the solution in a facility to showcase the capabilities of digitalization. During the implementation of solution, Intertec has identified many anomalies in the equipment and helped the client to enhance energy savings by optimizing the sequence of operations in the facility.

This integrated platform and FCX experience has helped the operations and maintenance team in several avenues to analyze the existing facilities and extend the capabilities in order to save energy and improve operational efficiency.

Outcome

- Energy Savings: Up to 50% of energy wastage is identified and rectified in a FAHU and real-time energy-saving updates in AED

- Centralized Process control and monitoring: Complete visibility on the process status, bottleneck, resource allocation

- Predictive Maintenance: The operations maintenance team can efficiently allocate resources and reduce downtime

- Inventory Cost Optimization: The customer is able to identify the degradation and redefine the stocks from proactive to reactive

- Integrated Platform to Unified Experience: seamless integration between BMS and highly Scalable to accommodate all the facilities